Automation | ConocoPhillips

Opgraderinger i styresystemer til forældelse af platform: ConocoPhillips

Strategiske ICSS-opgraderingsløsninger til offshore-platforme: Opretholdelse af produktion og sikkerhedsintegritet trods systemforældelse

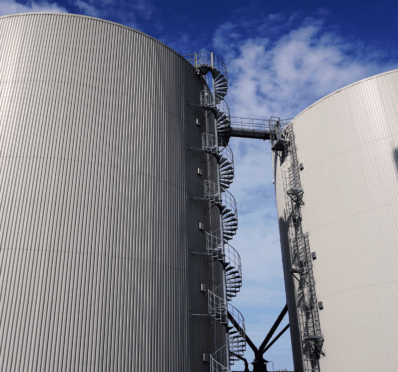

Som en del af ConocoPhillips’ J-Area, der består af produktionsfelterne Judy, Joanne, Jade og Jasmine, stod Judy-platformen over for udfordringer på grund af forældede styresystemer. Platformen, der ligger 240 km nordøst for Aberdeen, havde aldrende ICSS-controllere, som udgjorde en risiko for produktion og sikkerhed.

Init trådte til med en strategisk tilgang, der minimerede omkostninger og nedlukninger og muliggjorde fortsatte sikre operationer i de næste 10 år.

Ambition

Sikre produktion trods ældrede styringssystemer

Løsning

Feasibility-studie og strategisk systemopgradering

“Jeg vil gerne udtrykke vores taknemmelighed for den store dedikation, det hårde arbejde og de lange timer, der er blevet lagt i for at sikre, at vi med succes færdiggør opgraderingen af Judy’s ABB-noder. At have jer som en del af vores COP-hold gjorde vores succes mulig. Det har været et stort privilegium at arbejde sammen med jer som enkeltpersoner og Init som virksomhed.”

JOMP/Instrument & Automation Engineer