Automation | Stauning Whisky

Traditionel whiskyproduktion baseret på avancerede automationsløsninger

Stauning Whiskys topmoderne destilleri er udstyret med Inits intuitive brugerflade til styringssystemet

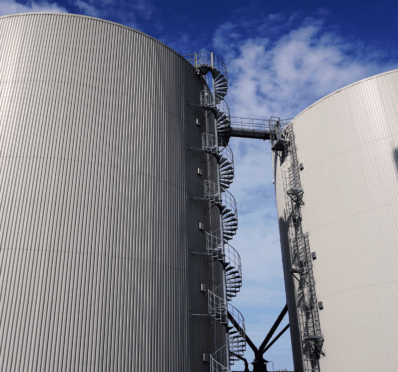

I udkanten af Stauning – en lille by i det jyske landskab – ligger et topmoderne og helt unikt whiskydestilleri, Stauning Whisky. Destilleriet, som blev opført i 2018, kombinerer traditionelle produktionsmetoder med innovative automationsløsninger og en banebrydende brugerflade.

Løsning

Automationssystemer kombineres med hjemmebyggede anlæg

Som ingeniører elsker vi muligheden for at knække en nød som denne – også selvom den er kompleks. For Init er det første gang, vi er en del af et stort, sammenhængende projekt, hvor alt foregår i TIA-portalen. Hele TIA-projektet har løftet vores forretning og gjort det muligt for os at integrere TIA-portalen i eksisterende anlæg – for eksempel inden for mejeri- og bryggeribranchen. Det styrker vores konkurrenceevne markant.

Klavs Vestergaard, Senior Project Manager at Init