Do you have the right Init?

Automation | Sundrop Farms

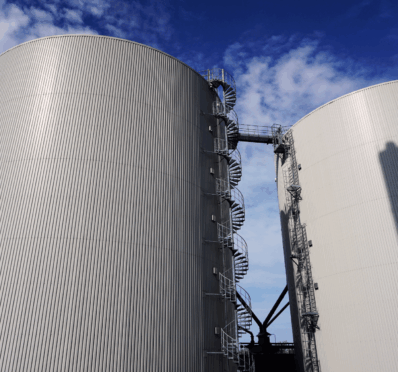

Tailored automation solution for cutting-edge greenhouse technology

Init delivered the automation solution for a new prestigious greenhouse concept at Sundrop Farms in Australia.

The Sundrop Farms grow high-value crops using seawater and sunlight. The greenhouse system harnesses the sun’s energy to convert seawater to freshwater for irrigation, electricity to power the greenhouse, and the energy to heat and cool the greenhouse crops.

Aspiration

Automating a first-of-its-kind greenhouse system

Solution

A reliable control system powered by experience & close collaboration

We are very proud and pleased to be a part of this great project in Australia. A project that once again draws on our core competencies and which will demonstrate the knowledge base we have built up during the past decades.

Troels Severinsen, Business Unit Director at Init.