Do you have the right Init?

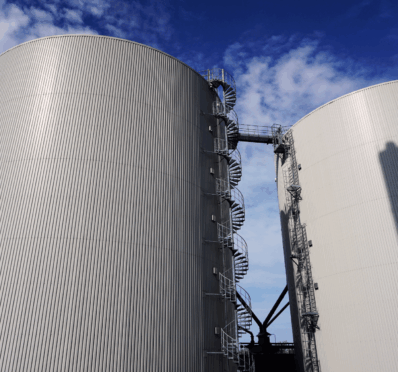

Automation | AkerBP/Ula field

Extending life of obsolete control systems at AkerBP's Ula field

Mitigating system obsolescence on the Ula field with strategic MP200 controller upgrades, extending operational life and ensuring safe, cost-efficient production.

As production assets in the Ula field continue to age, system obsolescence posed a significant risk to operational integrity. The outdated MP200 controllers, some over 20 years old, threatened unplanned shutdowns due to limited spare parts.

Init’s strategic upgrade approach helped extend the life of the control systems – ensuring safe, uninterrupted production well into 2025 and beyond.

Aspiration

Addressing obsolescence to prevent unplanned shutdowns

Solution

Strategic system upgrade for long-term reliability

Upgrading control and safety systems are always challenging. Init delivered this job on time and below budget with no impact to operations. Impressive!

Ella Kaliszuk, BP Ula/Tambar Area Operations Manager