Do you have the right Init?

Automation | Strandmöllen AB

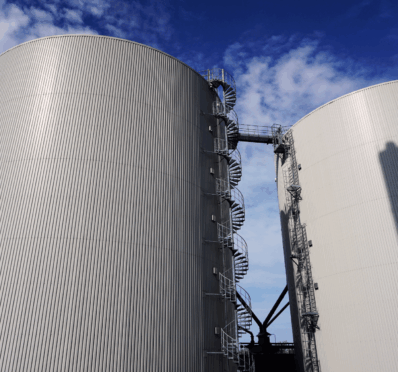

Efficient control systems ensure optimum hydrogen plant safety

Safety is a key priority at Strandmöllen's new fully automatic hydrogen plant. Init supplied PLC and SCADA programming for the plant’s integrated monitoring and process control system.

Christian Nielsen founded Strandmöllen in 1917. After his death in 1967, ownership of the company was transferred to the Christian Nielsen Foundation. From its inception, the group has pioneered many solutions for the gas industry. The group owns refuelling stations and plants that produce producer gas, hydrogen, CO2 and acetylene.

In 2023, Christian Nielsen Strandmøllen A/S began construction of a new 3-MW, 600 Nm3/h hydrogen plant at Strandmöllen AB, a subsidiary company located at Ljungby in Sweden. The aim is to establish a state-of-the-art gas production plant in combination with a refuelling station that is to function as simply and efficiently as a regular gas filling station.

Init supplied a control solution that is fully integrated with other Strandmöllen software platforms to optimise production processes, safety and monitoring.

Challenge

Safety is essential

Solution

Efficient monitoring and control

Result

Commissioning in 2025

Facts

About the plant

Reach out

for more information

Related

Manufacturing

Centrum Pæle

Init headed the extensive upgrade of the control system at Centrum Pæle's automated production facilities, resulting in reduced downtime and futureproof control setup. Read more

Manufacturing

FORCE Technology

Danish FORCE Technology has built the world's largest closed loop for calibrating flow meters. Init, which is FORCE Technology's automation partner on the project, has been responsible for all programming of the automation system. Read more