Do you have the right Init?

Automation | Centrum Pæle

Upgrade of control system on automated production plant

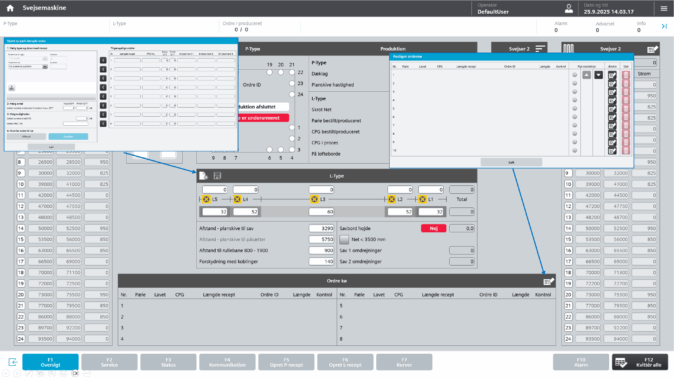

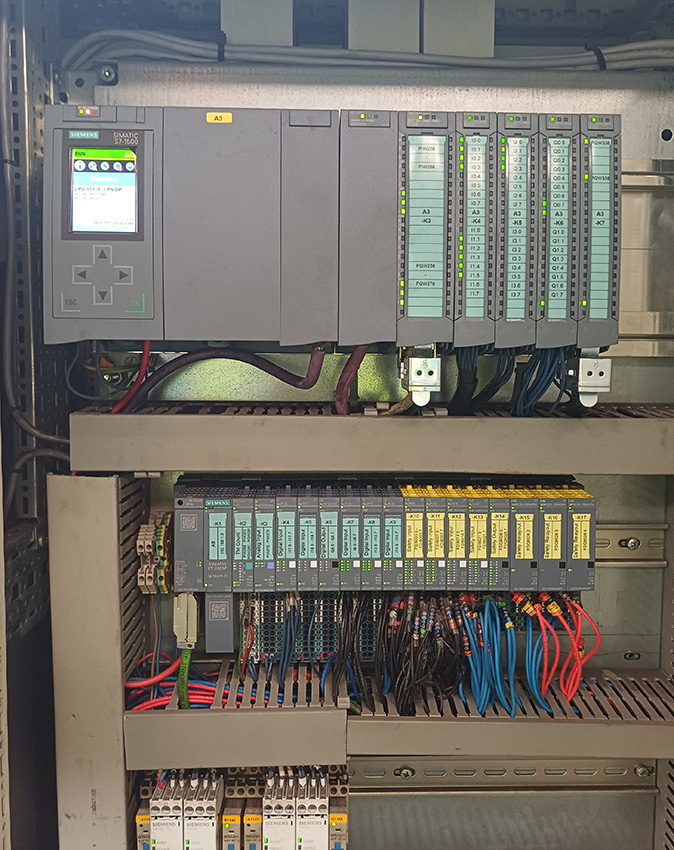

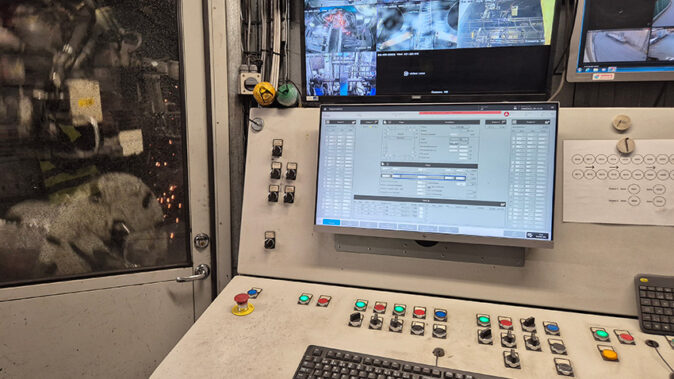

Init has been in charge of an extensive upgrade of the control system at Centrum Pæle's automated production facilities. The control was migrated from Siemens STEP7 to TIA and has helped to future-proof Centrum Pæle's production.

Centrum Pæle was established in 1965 and is primarily engaged in the production of foundation piles for the construction industry. For many years, the company has had a strong focus on continuously optimising production through automation.

This focus on automation is not only driven by an ambition to increase efficiency and reliability, but also to optimise the working environment and make work easier for employees by, for example, reducing heavy lifting or repetitive work.

Init fully shares this philosophy, and perhaps that is why we are one of Centrum Pæle’s preferred automation suppliers. We have many joint projects below our belts and in 2024 and the 1st half of 2025, we have together carried out a major upgrade of the control system across four of Centrum Pæle’s production units, which you can read more about below.

ambition

Future-proofing automated production plants

Solution

Upgrading both hardware and software

Migrating control from STEP7 to TIA

Init supported us with the upgrade of one of our cage welding machines. New Siemens PLC including safety modules and new IPC were combined to improve the performance and safety of the machine whilst ensuring continued support as obsolete hardware was replaced.

Thorough pre-install planning and support from Init being crucial to a smooth installation and commissioning, keeping production downtime to a minimum. The upgrade of our second cage welder is now planned following the success of the first.

Shaun Sutton, Plant Process & Improvement Manager, Centrum Pile, Newark