Automation | Brenntag

Automation process enables uniformity & versatility

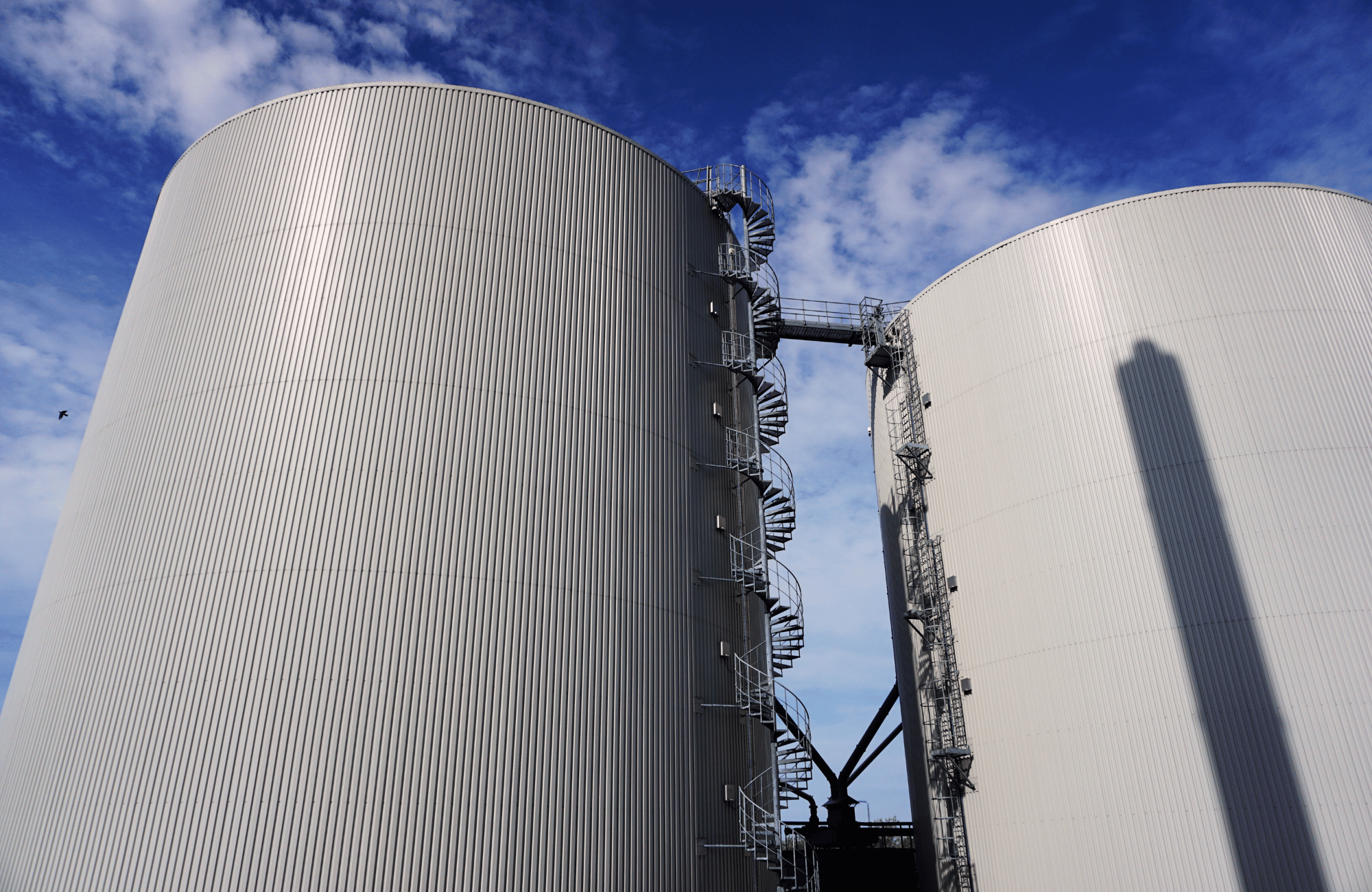

Thanks to its new, highly automated mixing system, chemicals and ingredients distribution company, Brenntag, has achieved more flexibility, better uniformity and full traceability.

When Brenntag asked the team from Init to develop a completely new, automated mixing system, the key word was flexibility. And that’s what they got: With the new facility, operators can create and change mixes fast and easily. The new mixing plant can handle up to 200 different chemical emulsions for the food, pharma, cleaning and metal industry. The facility itself is equipped with nine mixing tanks and about 25 raw material tanks.

We need flexibility across the board – everything has to be flexible including the mixing process itself, sequence, quantities, and so on. The system operates with a batch system that makes it easy for us to set up new recipes

explains Plant Manager, Poul-Erik Conradsen