Energy | Solnova

Control system for energy-efficient production of solar power

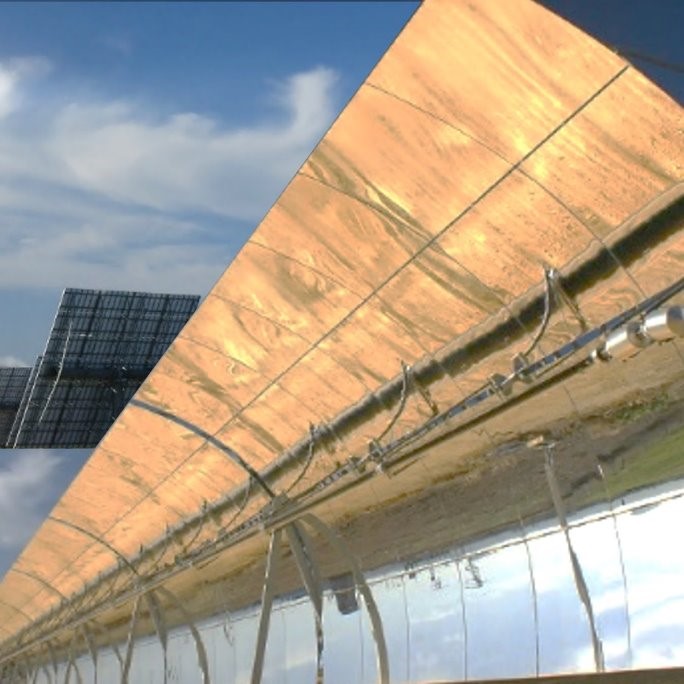

One of the world’s biggest solar power stations is the Solnova plant near Sevilla in Spain. The plant is based on concentrated solar power (CSP) designed by Danish Aalborg CSP and equipped with boiler control and switching system from Init.

Our favourite type of project is one where we can apply our process knowledge and automation skills combined with IT competences to develop solutions that support sustainable development. This project for Solnova is a great example of one such project.

Aspiration

Effective control of energy power plant

Solution:

Joint effort ensures robust control system

Result

Paving the way for Spain’s green transition

Fact box

Reach out

for more information

Related

Energy

ConocoPhillips

Init provided strategic ICSS upgrades for the Judy Platform, addressing obsolescence to maintain production and safety integrity. By developing a cost-effective plan, Init enabled ConocoPhillips to extend the life of its control systems while minimising downtime and ensuring compliance. See more