Automation | GrønGas

Optimisation of biogas plant with focus on operational stability

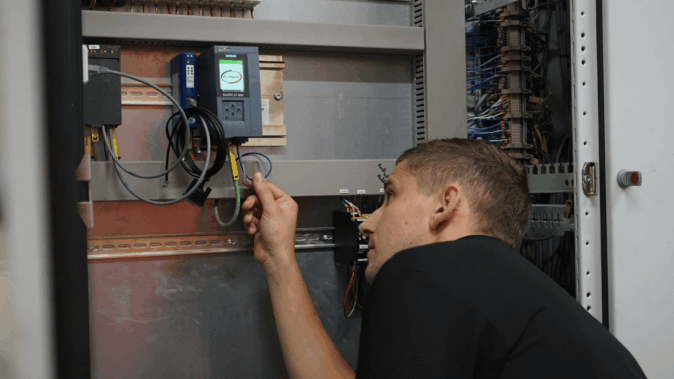

Init entered an R&D collaboration with the biogas plant GrønGas, focusing on increasing operational stability, reducing downtime, and improving service quality through systematic implementation of technical solutions and ongoing optimisations.

Through close dialogue, concrete actions, and continuous adjustments, Init met GrønGas’ requests regarding raw material sorting, gas quality, and operating conditions at their biogas plant.

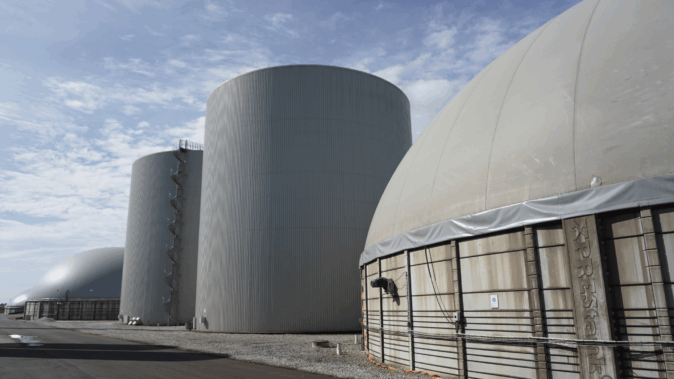

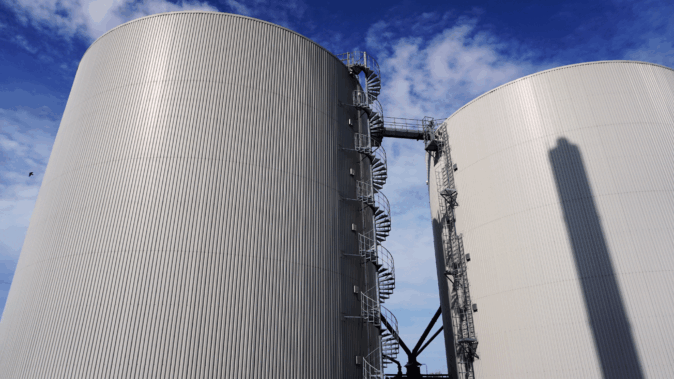

The biogas plant based in North Jutland, GrønGas, focuses on stable production of green gas at the company’s facility. The biogas company combines chemical and process engineering expertise with modern technology to deliver sustainable green gas to the Danish gas grid, benefiting both industry and private households.

Ambition

Robust solution for operational reliability & raw material flexibility

We have a plant that runs all the time, so if an error occurs, we need to react quickly. The most important thing for me is that it works and the service is high. That’s what we get with Init.

Christian Damsgaard, Operations Manager, GrønGas Vrå.