Automation | Heliac

Control system for a groundbreaking solar heating plant

The project is based on a new patented technology where the solar panels achieve temperatures of up to 200 degrees Celsius.

Heliac and Norfors have inaugurated the new plant, which is located in the DTU Science Park in Hørsholm. The solution will ensure CO₂-free heat for, among others, district heating and industrial companies that require high temperatures in production and normally use oil or natural gas. The plant can produce up to 1,700 MWh per year.

The concentrated sunlight heats a liquid, after which the control of the liquid’s flow rate ensures a controlled temperature level. The heat is then transferred by directing the liquid through a standard heat exchanger to the end user. Going forward, the plant will supply Norfors, which covers district heating for Fredensborg, Hørsholm, Rudersdal, Helsingør, and Allerød municipalities.

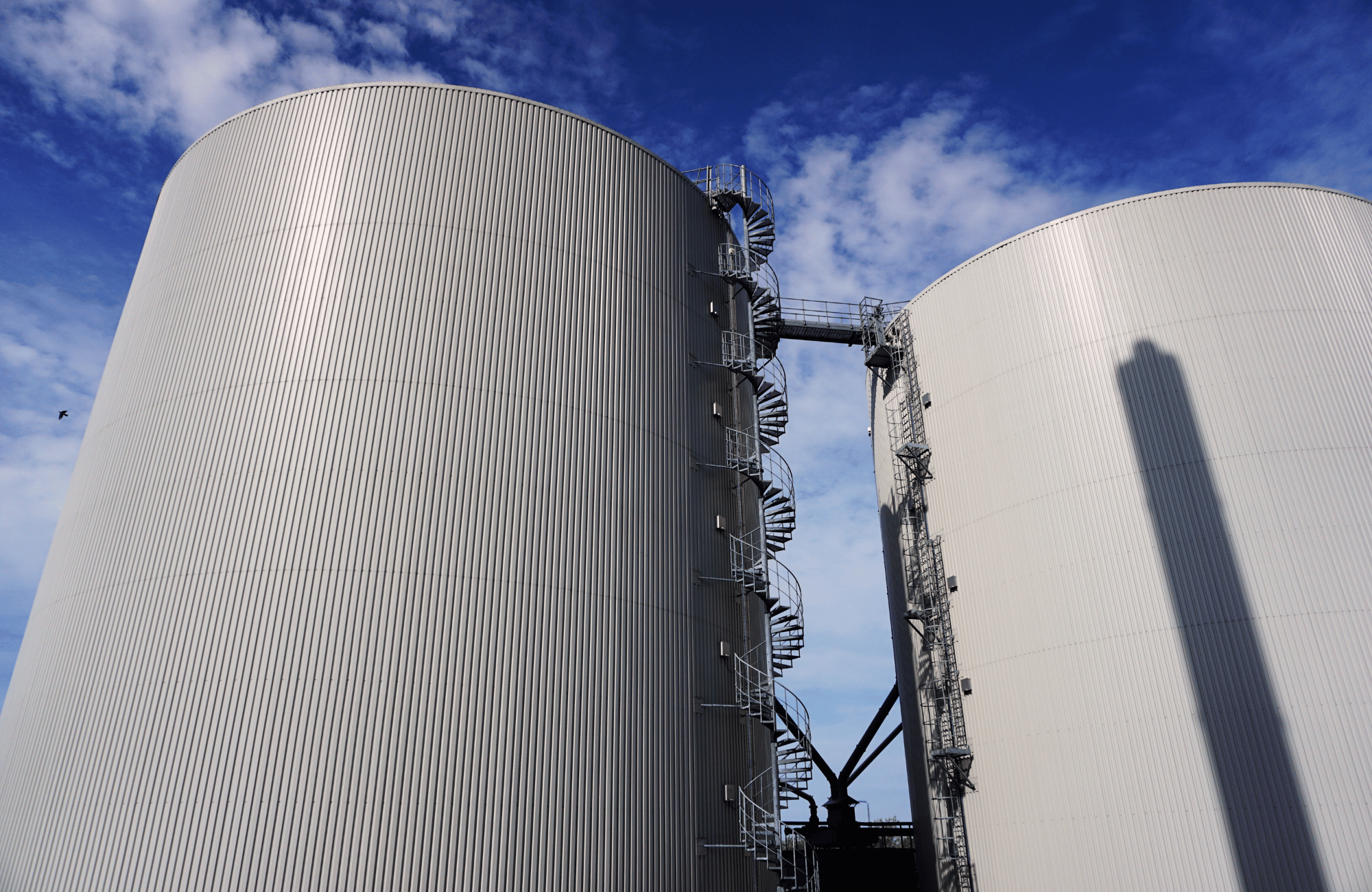

Init has carried out all automation related to the project, including control and regulation of the exchanger station and accumulation tanks.

Utilising surplus heat

In phase 2 of the project, the current accumulation tanks will be replaced by the latest heat storage system called “Rockstore.” Rockstore will be integrated into Norfors’ combined heat and power plant and will utilise varying surplus heat.

The future control and integration of Rockstore will also be carried out by Init.

Reach out

for more information

Niels Thye

Project Manager, Sales & Business Development Manager

Init Søborg, Denmark

Related

Manufacturing

Centrum Pæle

Init headed the extensive upgrade of the control system at Centrum Pæle's automated production facilities, resulting in reduced downtime and futureproof control setup. Read more

Energy

Strandmöllen AB

PLC and SCADA programming for hydrogen plant delivers effective control with specific focus on safety. Read more

Manufacturing

FORCE Technology

Danish FORCE Technology has built the world's largest closed loop for calibrating flow meters. Init, which is FORCE Technology's automation partner on the project, has been responsible for all programming of the automation system. Read more