Automation | SaltPower

Intelligent automation enables commercial production of breakthrough energy technology

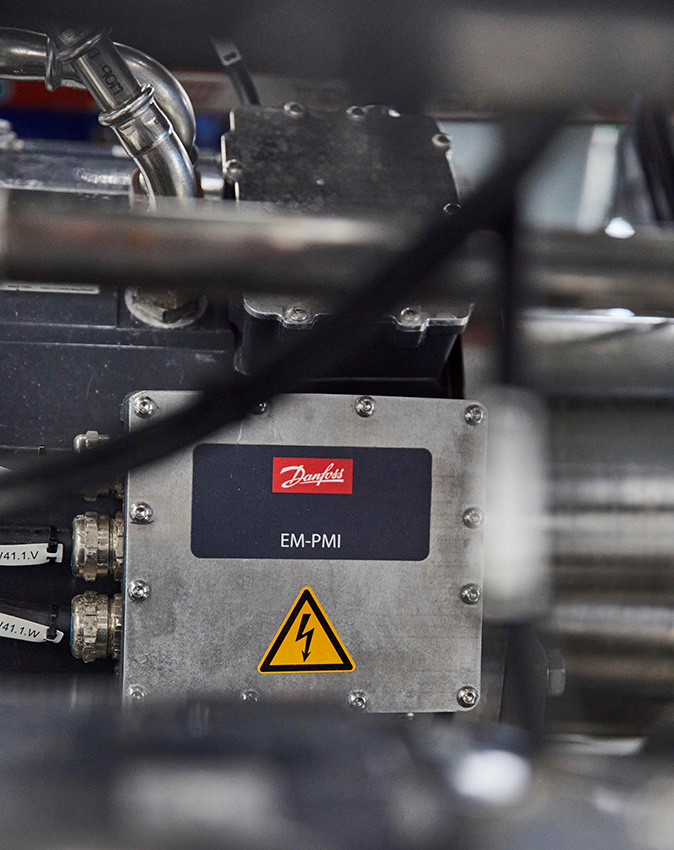

Init delivered the automation system for SaltPower's first clean energy plant based on osmotic energy.

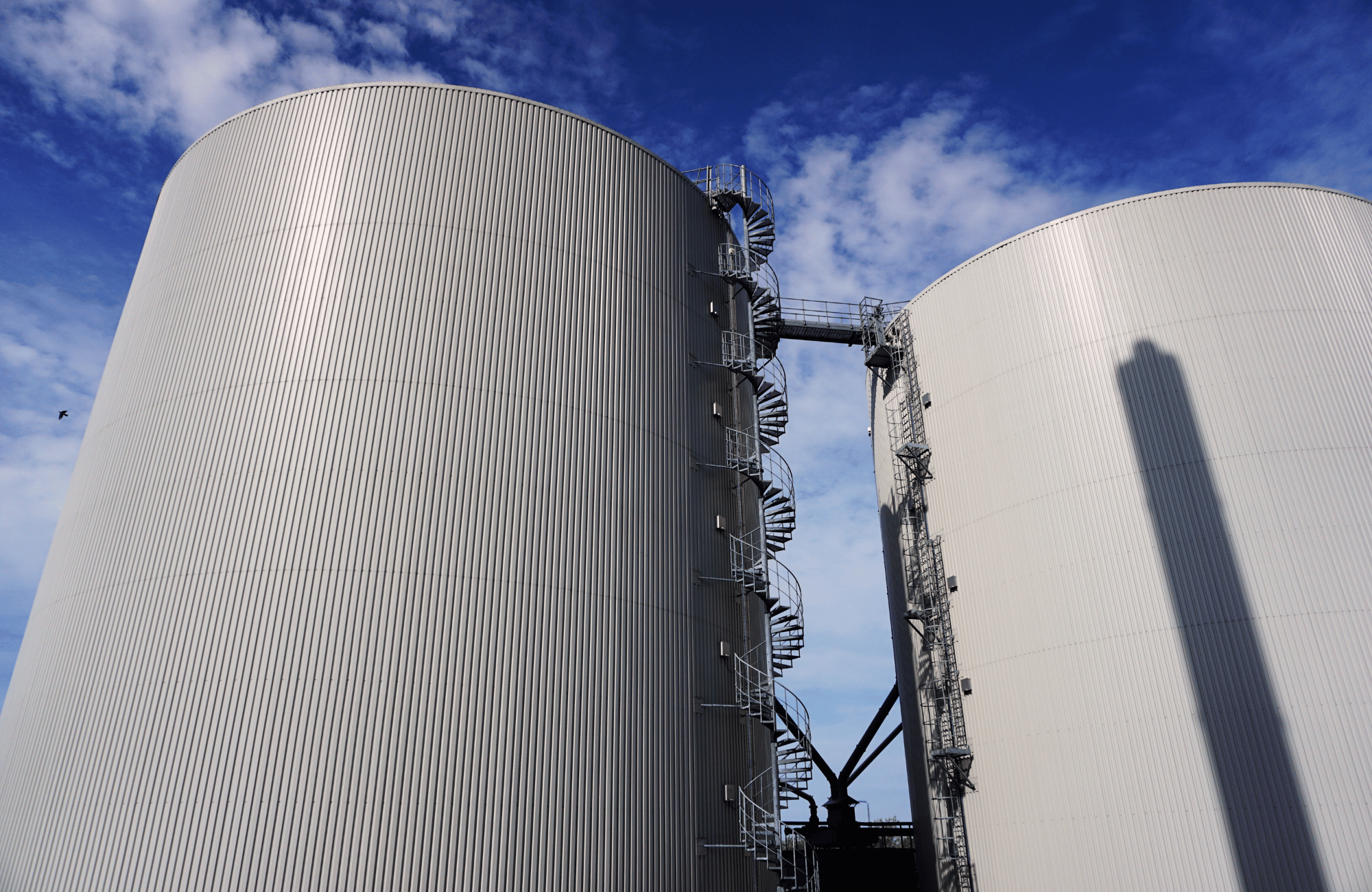

SaltPower – a Danish-based innovative clean energy company – has developed the world’s first commercial energy production technology based on osmotic energy. Specifically, SaltPower use salt water from the underground to produce clean and CO2-free energy.

The company has a full-scale test facility in Sønderborg, and since 2019, the company has been working with Danish salt manufacturer, DanskSalt/Nobian, with the purpose of testing its osmotic power installation. Following initial testing, SaltPower successfully established its first plant prototype in DanskSalt/Nobian’s factory in Mariager in 2021.

Aspiration

Automating a first-of-its-kind energy plant

Solution

Close collaboration & a fail safe control system

The collaboration with Init has worked flawlessly and the engineers involved have shown great enthusiasm and proactivity in the project.

Lars Storm Pedersen, CEO at SaltPower