Do you have the right Init?

Automation | Skagen Salmon

Automated, cloud-based solution increases efficiency in aquaculture facility

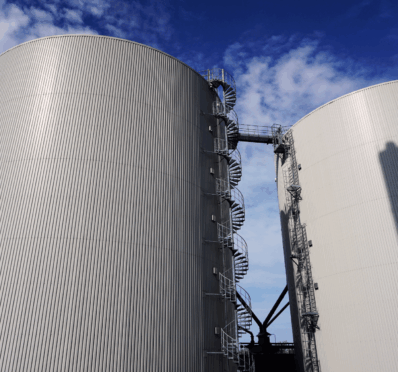

Init delivered an automated fish feed system, SCADA system and cloud solution for Skagen Salmon’s new fish farming facility.

Skagen Salmon’s facility for fish farming uses recirculation aquaculture system (RAS) technology. The highly automated facility has an annual capacity of 3,600 tonnes salmon. The fish are farmed in indoor tanks with grow out systems 1-6 and harvested at a weight of up to 4 kg.

Init delivered the fish feeding system, electrical panels as well as SCADA system and cloud solution for the facility.

Aspiration

Automated fish feeding system for higher efficiency

With Init’s Smart Fish Feeder we can automate the feeding process and at the same time, we can send production data to the cloud.

David Aroca, Grow Out RAS Manager at Skagen Salmon.