Do you have the right Init?

Automation | FORCE Technology

Complete automation solution for calibration of the world's largest flow meters

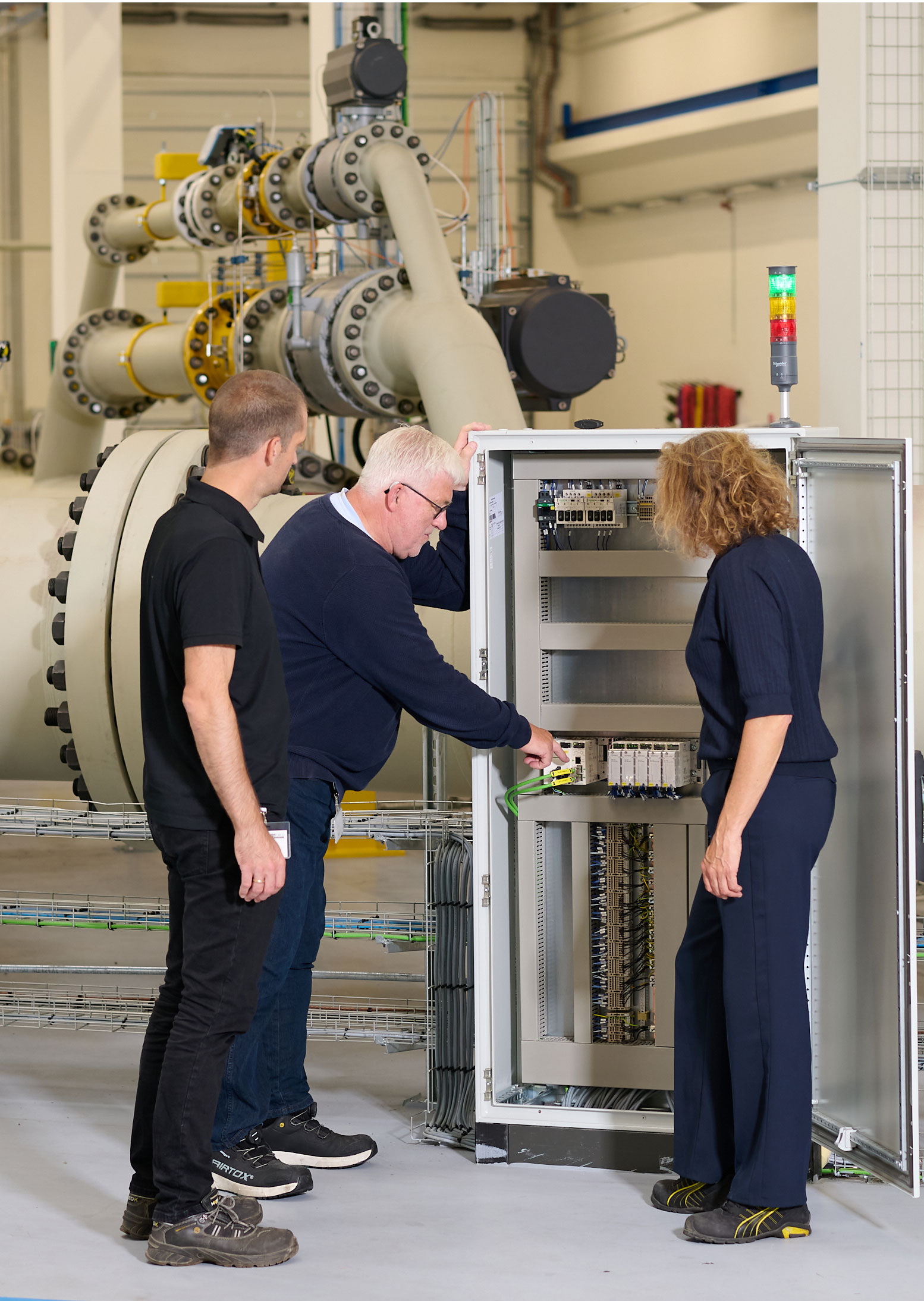

Accurate measurement of flow is essential for the world's supply of natural gas. Danish FORCE Technology has built the world's largest closed loop for calibrating flow meters. Init, which is FORCE Technology's automation partner on the project, has been responsible for all programming of the automation system, which is based entirely on Schneider Electric's complete automation platform EcoStruxure.

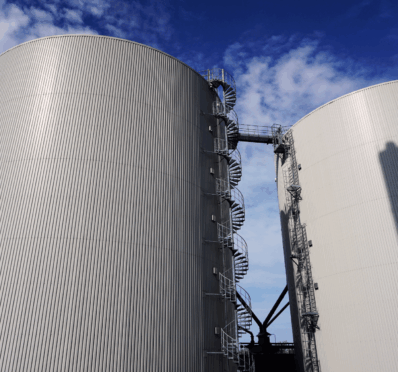

When the experts from FORCE Technology open the valves in the company’s new MEGA loop in Vejen, natural gas flows through the facility at up to 60,000 cubic meters per hour. Comparatively, a typical family home uses approximately 1,000 cubic metres in an entire year.

The enormous flow of natural gas is necessary when the task is to calibrate some of the world’s largest flow meters. The meters can have a diameter of up to as much as one and a half meters and are typically located on natural gas pipelines that cross national borders.

Challenge

Extremely high demands for process control

We place extremely high demands on all aspects of the plant and its operation. This applies to safety in general, cybersecurity, operational reliability, and not least quality, durability and support for all the components that are part of the control system.

Niels Ole Rud Olesen, Senior Programmer at FORCE Technology