Automation | Stauning Whisky

Traditional whisky production based on cutting-edge automation solutions

Stauning Whisky's top modern distillery is equipped with Init’s groundbreaking control system user interface

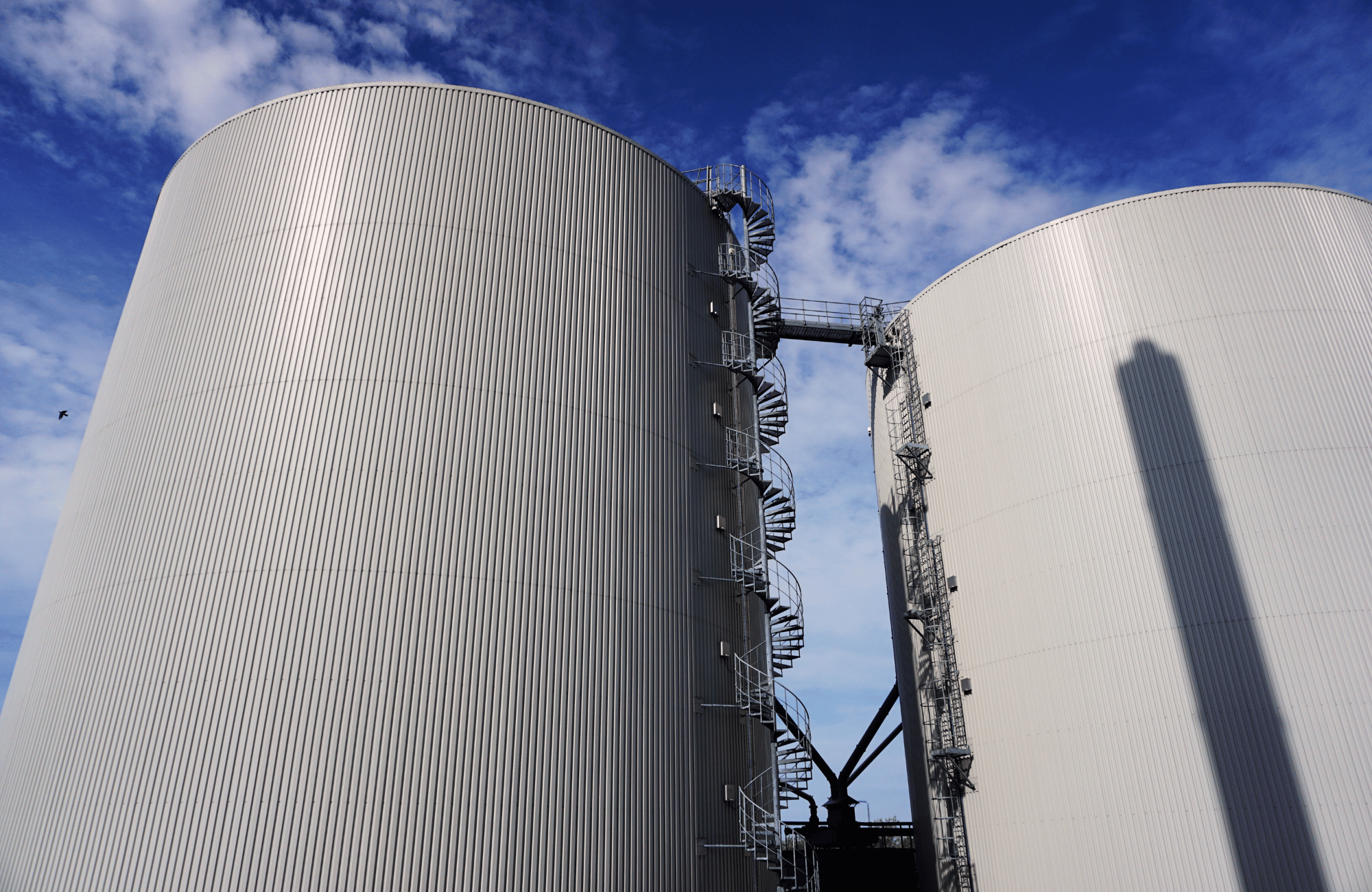

Just at the outskirts of Stauning – a small town in rural Jutland in Denmark – lies a top modern, one-of-a-kind whisky distillery. Built in 2018, the distillery combines traditional production methods with innovative automation solutions and a ground-breaking user interface.

Solution

Combining innovative automation systems with home-made equipment

As engineers, we love the chance to crack a nut like this one, even if it is complex. For Init, it is the first time that we are part of a large, continuous project, where everything takes place in the TIA portal. The whole TIA project has elevated our business and enabled us to integrate the TIA portal in existing facilities, for instance within dairy and breweries. That strengthens our competitiveness significantly.

Klavs Vestergaard, Senior Project Manager at Init